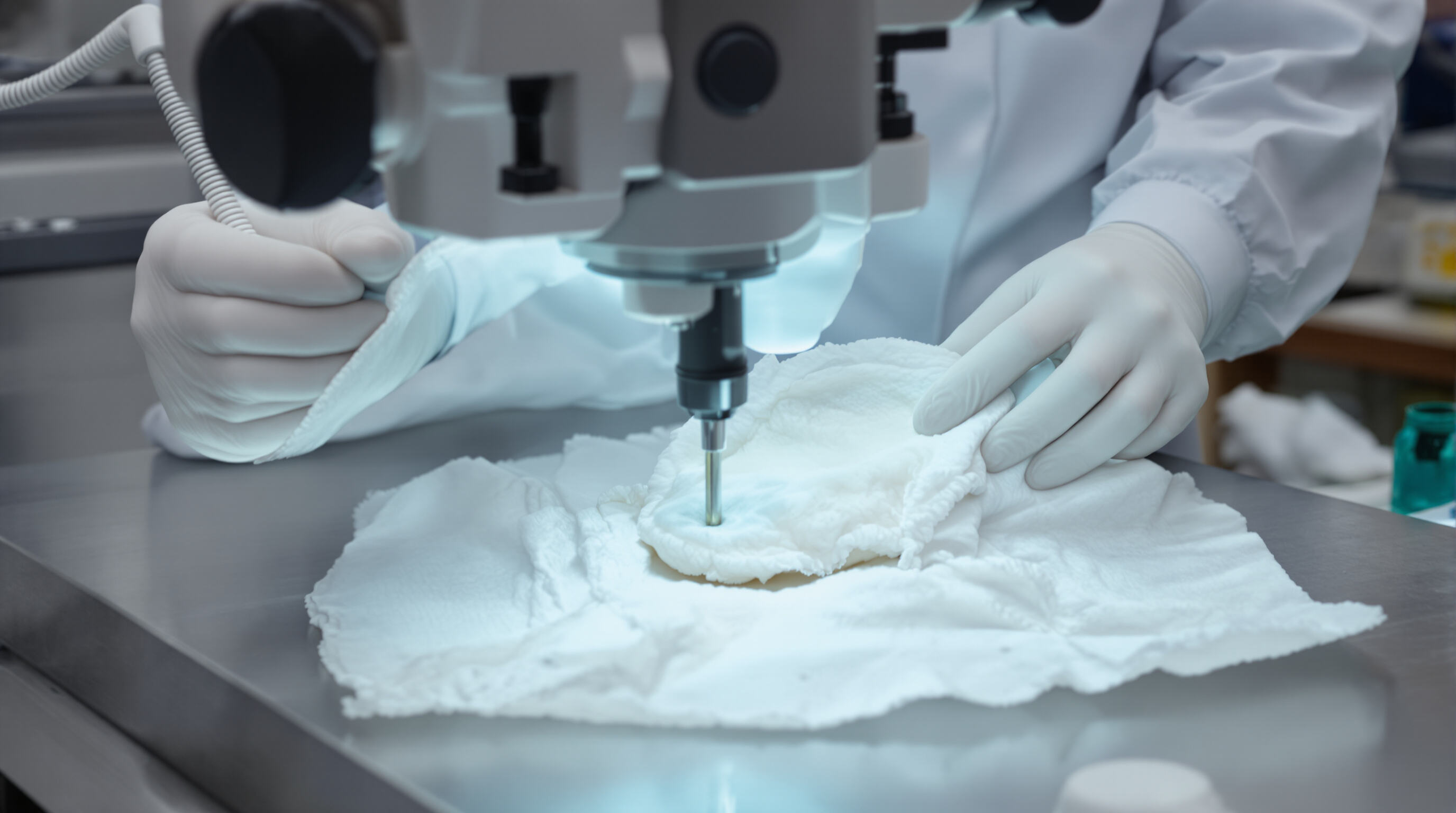

Bəbək pətələrinin soruculuğu iddialarını təsdiqləmək üçün laboratoriya test tərəfdaşlıqları

Bəbək pətisinin sorbəyici təsdiqlənməsi üçün müstəqil laboratoriya testlərinin vacibliyi

İstehsalçının şəffaflığını müstəqil təsdiqlə təmin etmək

Müstəqil laboratoriyalar beb bəziyələrini test edərkən, onlar ISO 9001 udma yoxlaması kimi standart testlərdən istifadə edərək istehsalçının tərəfdaşlığını aradan qaldırırlar. Ən son araşdırma keçən il 37 müxtəlif bəzi markalarını nəzərdən keçirdi və maraqlı bir kəşf etdi: təxminən üçdə biri məhsullarının real laboratoriya şərtlərindən çox maye udma iddiasında tapıldı. Bəzi markalar udma göstəricilərini 15%-dən artıq abartırdılar. Üçüncü tərəf təsdiqləmə əldə etmək bu məhsulların həqiqətən də vacib performans hədəflərinə çatdığı anlamına gəlir. Məsələn, əksər bəziyələrin gecə boyu qoruma vədində tapılan yuxusuz valideynlərə sızma olmadan təxminən 500 ml maye saxlaması lazımdır.

Akreditə edilmiş laboratoriyalar beb bəzi markalarına olan istehlakçı etimadını necə qurur

Good Housekeeping-in Teksil Laboratoriyasında testlər aparan kimi düzgün akkreditasiyaya malik laboratoriyalar, paltarları idarə olunan şərtlərdə təxminən 12 saat geyinən vəziyyətlər yaradır. Onların 2024-cü il testlərinin nəticələri maraqlı bir şeyi aşkar etdi: tərəfli ekspertlər tərəfindən təsdiqlənən paltarlar dəri rütubətini sübutsuz iddialar irəli sürən brendlərlə müqayisədə təxminən 62% azaltdı. İnsanlar bu cür həqiqi testlərə inanırlar. Son sorğu göstərdi ki, yaxın vaxta qədər valideynlərin 80%-i paltar alarkən şirkətlərin məhsulları haqqında dediklərinə əsaslanmaqdan əlavə rəsmi laboratoriya nişanlarını xüsusi olaraq axtarır.

Tədqiqat nümunəsi: Öndə gedən uşaq paltarı brendləri və onların laboratoriya testi tərəfdaşlıqları

Bir çox aparıcı şirkət ISO 17025 standartları altında sertifikatlaşdırılmış laboratoriyalardan illik sorbəsiya hesabatları çıxarmağa başlayıb. Məlum bir brend NSF International ilə testlər üçün əməkdaşlıq edib və məhsulun dizaynını laboratoriyanın tapıntılarına əsasən düzəliş etdikdən sonra sızma ilə bağlı müştəri şikayətlərində kəskin azalma müşahidə edilib. Başqa bir istehsalçı hər üç ayda bir Intertek-in filiallarında yoxlanmaqla öz sorbəsiya iddialarına ticarətçilərdən tam təsdiq ala bilib. Bu nümunələr bu gün müstəqil test təşkilatları ilə əlaqə saxlamanın nə qədər vacib olduğunu göstərir. Məhsullar faktiki texniki xüsusiyyətlərə cavab verdikdə istehlakçılar onlara daha çox inanır ki, bu da nəticədə satışların artmasına və geri qaytarmaların azalmasına səbəb olur.

Sorbəsiya Çərçivəsinin Səmərəliliyinin Qiymətləndirilməsi: Üsullar və Sənaye Etalonları

İstifadə Şəraiti Testləri: Sorbəsiya Həcminin Reallığa Yaxın Şərtlərdə Qiymətləndirilməsi

Ən son test üsulları, 5,8 psi təzyiqədək olan materiallara təzyiq edərkən və mayenin nə qədər saxlandığını yoxlayarkən, necə hərəkət etdiklərini bərpa etməyə çalışır. Keçən il Tələbələrin Təhlükəsizliyi Hesabatından çıxan yenilənmiş WSP 70.10 təlimatlarına əsasən, ən yaxşı pətiklər 450 ml duzlu su qarışığının təxminən 98 faizini təkrar-təkrar sıxılsa belə saxlaya bilir. Laboratoriyalar bu eksperimentləri dəfələrlə yerinə yetirərək gecələr təkrarlanan yuxu zamanı baş verən vəziyyəti təqlid edirlər. Yüksək keyfiyyətli məhsullar üçün istehsalçılar, yarım millilitrdən artıq həcmi qəbuledilməz hesab edəcək qədər yüksək standartlar müəyyən edərək, heç bir sızmanın olmamasına çalışırlar.

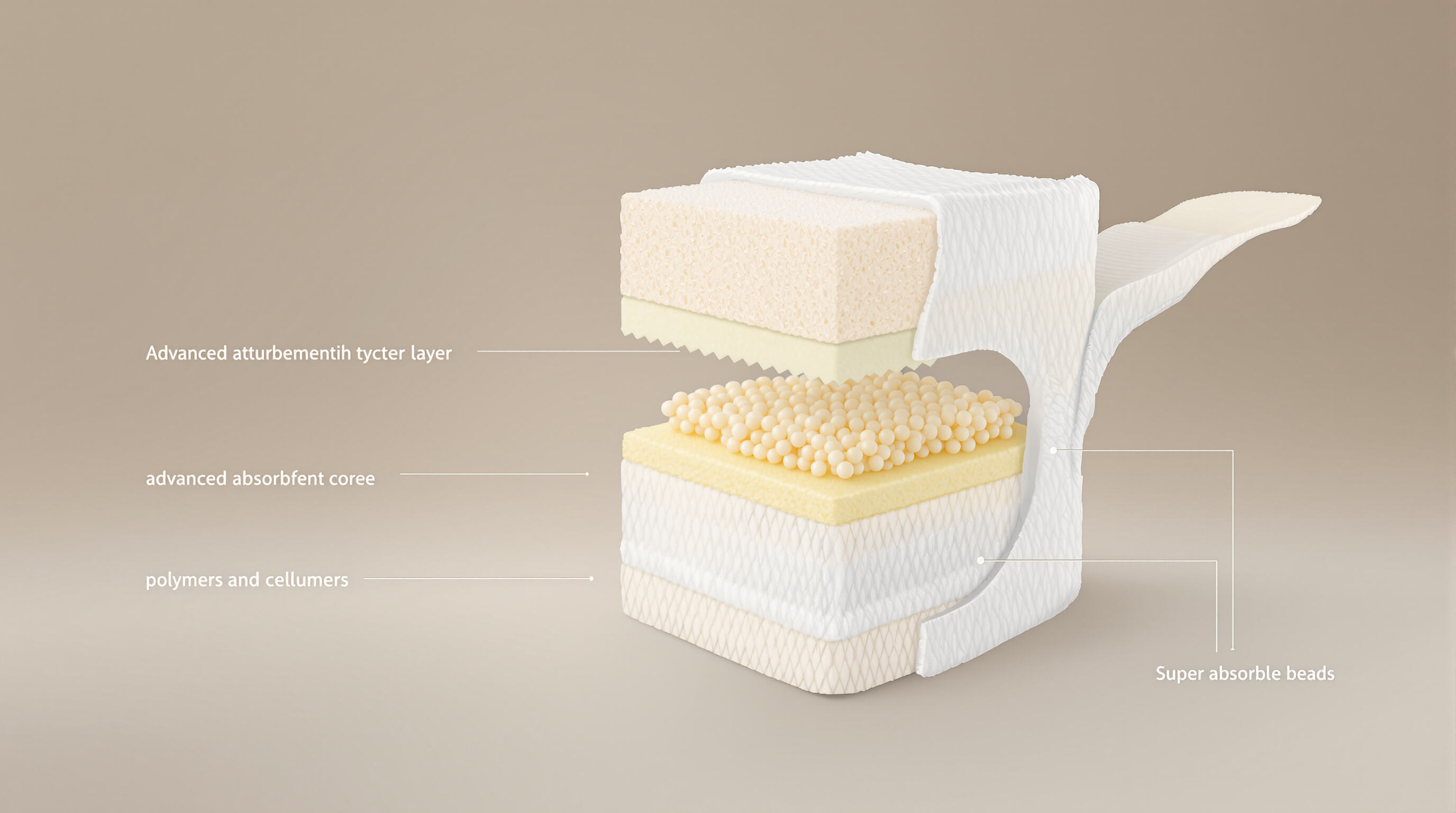

Daxili Tərkibin Tədqiqi: Polimer Paylanması və Yoğunluğu Bebek Pətiklərində

Yüksək dəqiqlikli KT müayinələri və penetrasion testlər keyfiyyət fərqlərini aşkar edir. Sənaye liderləri nüvə zonalarında superabsorbent polimer (SAP) sıxlığını 30% -dən yuxarı saxlayır, bədəncik variantları isə 18–22% arasında dəyişir. 2023-cü ilin müqayisəli analizi bərabər SAP paylanmasının toplanmış konfiqurasiyalara nisbətən sorulma sürətini 40% artırdığını göstərdi.

2023-cü ilin məlumat analizi: Top bezi brendləri üzrə orta sorulma həcmi

| Brend səviyyəsi | Orta sorulma (ml) | Sızma nisbəti (ml) |

|---|---|---|

| Premium | 480–510 | 0.2–0.4 |

| Orta diapazon | 420–460 | 0.6–1.1 |

| Ekonomika | 380–410 | 1.3–2.8 |

Tərəfdaş məlumatlar premium pətiklərin iqtisadi səviyyədən 22% daha çox maye udma qabiliyyətinə malik olduğunu və sızma riskini 84% azaltdığını göstərir (Global Hygiene Lab, 2023).

Bəslənmə Qabiliyyəti Üzrə Hiperbolizə Edilmiş İddiaların Həllinə: Laboratoriya Nəticələri və Marketinq Vədələri

Müstəqil testlər 32% brendin udma həcmini 15–20% artdıqda göstərdiyini aşkar edib. JPMA Uşaq Məhsulları İstehsalçıları Assosiasiyası jPMA sertifikatı üçün üçüncü tərəfin təsdiqini tələb edir; 2023-cü ildə yeddi böyük istehsalçının sertifikatı əsaslandırılmamış iddialar səbəbindən ləğv edilib.

Dəri Sağlamlığı Üzərində Təsirinin Qiymətləndirilməsi

Sürətli Udma Elmi və Dəri Quruluğunun Saxlanması

Effektiv uşaq pətikləri 30 saniyədən az müddətdə mayeni udur, dəri üzərindəki nəmliyə məruz qalma müddətini minimuma endirərək. Tədqiqatlar göstərir ki, uzun müddətli nəmlik dəri xəstəliyi riskini 73% artırır (Pediatrik Dermatologiya Jurnalı, 2023). İnkişaf etmiş nüvələr dəridən uzaqlaşdırmaq üçün kapilyar hərəkətli polimerlərdən istifadə edir, yuxarı təbəqəni quru saxlayır və dəri sağlamlığını dəstəkləyir.

Bəbək pətisinin sorbə edici səmərəliliyini yoxlamaq üçün laboratoriya protokolları

Müvafiq laboratoriyalar SGS-IPS NWSP 70.9 standartlarına əsasən simulyasiya edilmiş təkrar sidik ifrazı testləri istifadə edərək sorbə effektivliyini qiymətləndirir, bir neçə nəm hala gətirmə üzrə ilkin sürəti və performansı ölçür. Əsas göstəricilərə daxildir: SGS-IPS NWSP 70.9 standartları, bir neçə nəm hala gətirmə üzrə ilkin sürəti və performansı ölçür. Əsas göstəricilərə daxildir:

- Təkrar nəmlik dəyəri (15 qramdan az effektiv quruluğu göstərir)

- Sorulma müddəti (premium pətislər üçün 25 saniyədən az)

- Ümumi sorbə tutumu (500 ml və ya daha çox gecə müdafiəsi üçün)

Tərəfdaş qiymətləndirmələri 2023-cü ilin məlumatına görə məhsulların 34%-in reklamda sorbsiya sürətini 8-12 saniyə qədər artıraraq göstərdiyini bildirir (Qlobal Gigiyena Şurası, 2023).

İnnovasiya işıqlandırması: Premium bezi məmulatlarında sürətli sorulma texnologiyaları

Ən iri brendlər istifadə edir asimmetrik yayım kanalları və pH-neytral super sorucu polimerlər (SAP) sürətləndirmək üçün. 2023-cü ildə materialşünaslıq sahəsində qazanılan uğurlar göstərdi ki, kəsişərək birləşdirilmiş sellüloza-SAP hibridləri təkrar nəmlənmə dərəcəsini konvensiya dizaynlarına nisbətən 41% azaldır. Yeni yaranan termoresponsiv sorulma təbəqələri bədən istiliyinə məruz qaldıqda daha sürətli nəm udma aktivləşdirir və beləliklə hərəkətli zamanlarda nəm saxlama keyfiyyətini artırır.

Yüksək səmərəli uşaq pətisinin arxasında duran material və konstruksiya innovasiyaları

Maye nəmliyin daha yaxşı udulmasını və yayılmasını təmin edən inkişafetmiş nüvə dizaynları

2023-cü ilin Sorbent Materiallar Araşdırmasına əsasən, müasir nüvələr ənənəvi dizaynlardan 2,3 dəfə daha sürətli nəmlik udur. SAP-lərin hava ilə qurudulmuş sellüloz lifləri ilə birləşdirilməsi 12 saatlıq simulyasiya edilmiş istifadə zamanı 97,8% maye saxlama effektinə nail olur. Xətti polimer şəbəkələri mayeni nüvənin 93%-inə paylayır və 2020-ci il modelləri ilə müqayisədə lokal doyma səviyyəsini 41% azaldır.

Uşaq pətisi istehsalında davamlı materiallar və FSC sertifikatlı qablaşdırma

böyük istehsalatçıların 67%-i artıq FSC sertifikatlı ağac şoraları və bitki əsaslı SAP alternativlərindən istifadə edir. Şəkər qamışı əsasında hazırlanmış polietilen arxa təbəqələrə keçid hər bir milyon pəti istehsalı zamanı karbon emissiyalarını 18,4 ton azaldır. Səkkiz aparıcı brend 2026-cı ilə qədər 100% bioloji parçalanan qablaşdırmağa keçməyə söz verib və pilot bazarlarda qida nişastası əsaslı film qablaşdırmalar artıq plastik tullantıları 28% azaldıb.

OEKO-TEX Sertifikatı: Dəriyə təhlükəsiz və zəhərsiz uşaq pətəklərinin istehsalını təmin etmək

OEKO-TEX Standart 100 216 qadağan olunmuş maddəni aradan qaldırır, o cümlədən ftalatlar və formaldehid. Sertifikatlı materiallar yeni doğulmuşların dəri mikroflorasında pH balanssızlığı riskini 71%-ə qədər azaldır. 1200 pediatr dermatoloqun iştirakı ilə 2024-cü ildə keçirilən klinik sorğuya əsasən, 82%-dən çoxu ekzema və ya həssas dəriyə malik körpələr üçün OEKO-TEX sertifikatlı pətəkləri tövsiyə edir.

Gələcək Tendensiyalar: Bioloji parçalanma qabiliyyətinə malik polimerlər və yeni nəsil sorbent strukturlar

Bioloji parçalanma qabiliyyətinə malik poliqlaktid turşusu (PLA) nüvələri konvensiya SAP qarışıqlarına nisbətən 11 dəfə sürətli parçalanır. Həcimi sorbent kameraya malik prototiplər hərəkət testi zamanı 35% daha yaxşı sızma müqaviməti göstərir, şaquli fitil kanalları ilə 3D strukturlu nüvələr isə 2025-ci ilin sonuna qədər kütləvi istehsala çıxacaq.

Tez-Tez Soruşulan Suallar

Uşaq pətəkləri üçün üçüncü tərəf laboratoriya testlərinin aparılması nə üçün vacibdir?

Üçüncü tərəfin laboratoriya testləri pətək performansı iddialarını yoxlamağa kömək edir və bazar mühitində şəffaflıq və etimadın yaradılmasına zəmin yaradır.

Hansı növ laboratoriyalar bu testləri aparır?

Good Housekeeping-in Teksil Laboratoriyasının və ya NSF International-in istifadə etdiyi akkreditasiya edilmiş laboratoriyalar bu cür testlərdə ümumiyyətlə iştirak edir.

Bu testlər tələbələrə necə kömək edir?

Laboratoriya testləri tələbələrə etibarlı məlumatlar verir və onlara həqiqətən sorulma və təhlükəsizlik standartlarını təmin edən pətikləri seçməkdə kömək edir.

Pətik sənayesində hansı innovasiyalar meydana çıxır?

İnnovasiyalar bioloji parçalanma qabiliyyətinə malik materiallar və PLA nüvələri və assimetrik yayılma kanalları kimi irəliləmiş sorucu strukturları daxil edir.