Kontrolní seznam specifikací OEM pro noční hygienické vložky s vysokou vstřebávací kapacitou

Porozumění kapacitě a udržení tekutin u nočních hygienických vložek

Pokud jde o to, jak dobře noční hygienické vložky pohltit tekutiny, existují opravdu dva hlavní faktory, které jsou nejdůležitější. Prvním je objemová kapacita, tedy množství tekutiny, které může podložka celkem pojmout. Druhým je účinnost udržení tekutiny, která udává, jak dobře je tekutina v podložce udržována i při tlaku. Většina hlavních výrobců usiluje o to, aby jejich výrobky dokázaly zvládnout 350 až 500 mililitrů tekutiny bez toho, aby se během testování, které napodobuje skutečné pohyby těla podle norem jako ISO 11948-1 z roku 2020, uniklo více než přibližně 5 %. Co způsobuje, že tyto podložky fungují tak dobře? Hodně záleží na směsi uvnitř vstřikovacího jádra. Nejlepší výkonnost obvykle přináší kombinace celulózových vláken a superabsorbujících polymerů v poměru zhruba 60 ku 40. Tato kombinace pomáhá udržovat suchost tím, že lépe váže vlhkost a snižuje pravděpodobnost, že podložka po nasátí tekutiny znovu zvlhne.

Význam rychlosti absorpce a odolnosti proti zpětnému navlhčení pro pohodlí uživatele

Rychlost, jakou menstruační tekutina proniká z vrchní vrstvy do vstřebávacího jádra, je rozhodující pro vyhnutí se nepříjemným mokrým místům na povrchu. Výzkum zveřejněný v Journal of Textile Science v roce 2022 zjistil, že vložky, které tekutinu vstřebají do tří sekund, snižují kontakt s vlhkostí na kůži o přibližně 72 % ve srovnání s vložkami pomalejšími. Při hodnocení tzv. rewetu (zpětného úniku tekutiny) se sleduje, zda se tekutina po vstřebání nevrací zpět na povrch. Standardní test tuto hodnotu měří jako uvolnění kolem půl gramu tekutiny pod určitým tlakem. V praxi to znamená větší suchost během dlouhých nocí spánku, což zvyšuje pohodlí i sebedůvěru uživatelky po celém menstruačním cyklu.

Zkušební normy pro silně vstřebávací hygienické vložky (ISO 11948-1)

Norma ISO 11948-1 hodnotí výkon hygienických vložek prostřednictvím tří klíčových metod:

- Gravimetrická analýza : Simulace menstruace pomocí syntetické krve při teplotě 37 °C

- Test odstředivé retence : 1 200 otáček za minutu pro měření úniku

- Odolnost vůči tlaku : 50N síla napodobující polohu sedícího nebo ležícího

Vložky dosahující certifikace úrovně 4 – nejvyšší možná – udrží ≥95 % z 400 ml tekutiny ve všech testech a stanoví tak standard pro prémiovou ochranu přes noc.

Srovnání dat: Úroveň vstřebávací kapacity u modelů předních OEM značek

| Metrické | Úroveň pro úsporné modely | Střední třída | Prémiové |

|---|---|---|---|

| Průměrná kapacita (ml) | 280 | 360 | 420 |

| Poměr retence | 82% | 91% | 96% |

| Výkon při opakovaném navlhčení | 1,8G | 0.9g | 0.4g |

| Shoda s normou ISO 11948-1 | Úroveň 2 | Úrovně 3 | Tier 4 |

Při použití modelů vyšší třídy je během noci o 40 % vyšší ochrana díky vícevrstvovým jádrům s různou hustotou, která optimalizují jak kapacitu, tak komfort.

Konstrukce jádra a ochrana proti úniku tekutin u nočních hygienických vložek

Návrh vstřebávacího jádra pro zvýšenou retenci tekutin a ochranu proti úniku

Dnešní noční vložky kombinují běžnou celulózovou vatu se zvláštními silně vstřebávajícími polimery, které nazýváme SAPs. To znamená, že mohou udržet více než 40 ml na čtvereční centimetr podle údajů HyFACTS z minulého roku. Novější kanálové konstrukce jader výrazně zrychlují vstřebání tekutin ve srovnání se staršími plochými konstrukcemi – dokonce zhruba dvojnásobně – a to pomáhá odvádět vlhkost z míst, kde není žádoucí. Některé pokročilé modely nyní používají tyto moderní materiály zhotovené technologií airlaid, které jsou svisle vrstvené namísto toho, aby byly rozmístěné vodorovně, čímž se snižuje riziko úniku tekutin na boky, když si člověk leže na zádech během spánku. To má velký význam pro lidi, kteří potřebují ochranu po celou noc.

Technologie zónového jádra a kanálové rozvody ve vysoko vsáklých obkladech

Strategicky umístěné materiály vytvářejí tři funkční zóny:

- Rychlé kanály pro příjem (SAP skupiny s vysokou pórovitostí) ve středu

- Zóny pro udržení podél okrajů k udržení tekutin

- Kapilární mosty spojující zóny pro zlepšení rozvodu

Tato zónová konstrukce zvyšuje účinnost využití SAP o 33 % a snižuje objem jádra o 15 %, čímž nabízí vysoký výkon bez přidané tloušťky.

Vliv hustoty a tloušťky jádra na ochranu přes noc

| Metrické | Optimální dosah | Vliv na výkon |

|---|---|---|

| Jádrová hustota | 0,35–0,45 g/cm³ | Vyšší hustota zlepšuje retenci, ale snižuje pružnost |

| Tloušťka | ≤6,5 mm | Tenčí profily zvyšují pohodlí, aniž by byla ohrožena kapacita |

| Záchrana z komprese | ≥85% | Udržuje strukturální integritu po dlouhodobém tlaku |

Testování dle ASTM F3160-24 ukazuje, že variace hustoty přesahující 0,1 g/cm³ zvyšují riziko úniku o 22 % v nočních simulacích.

Případová studie: Přepracování struktury jádra pro prevenci úniku po dobu 12 hodin

Inženýrský test z roku 2024 upravil poměr celulózy k SAP z 3:1 na 2,4:1 ve vrstvě sekundárního jádra, čímž došlo k následujícím výsledkům:

- zlepšení odolnosti proti zpětnému navlhčení o 40 %

- 27% snížení boční migrace tekutin

- Ověřená 12hodinová ochrana podle ISO 11948-1

Asymetrický vzor jádra dosáhl 95% prevence úniku v simulacích spánku na boku, čímž byl vyřešen dlouhodobý problém při návrhu nočních vložek.

Superabsorbující polymery (SAP) a inovace materiálů ve výkonu vložek

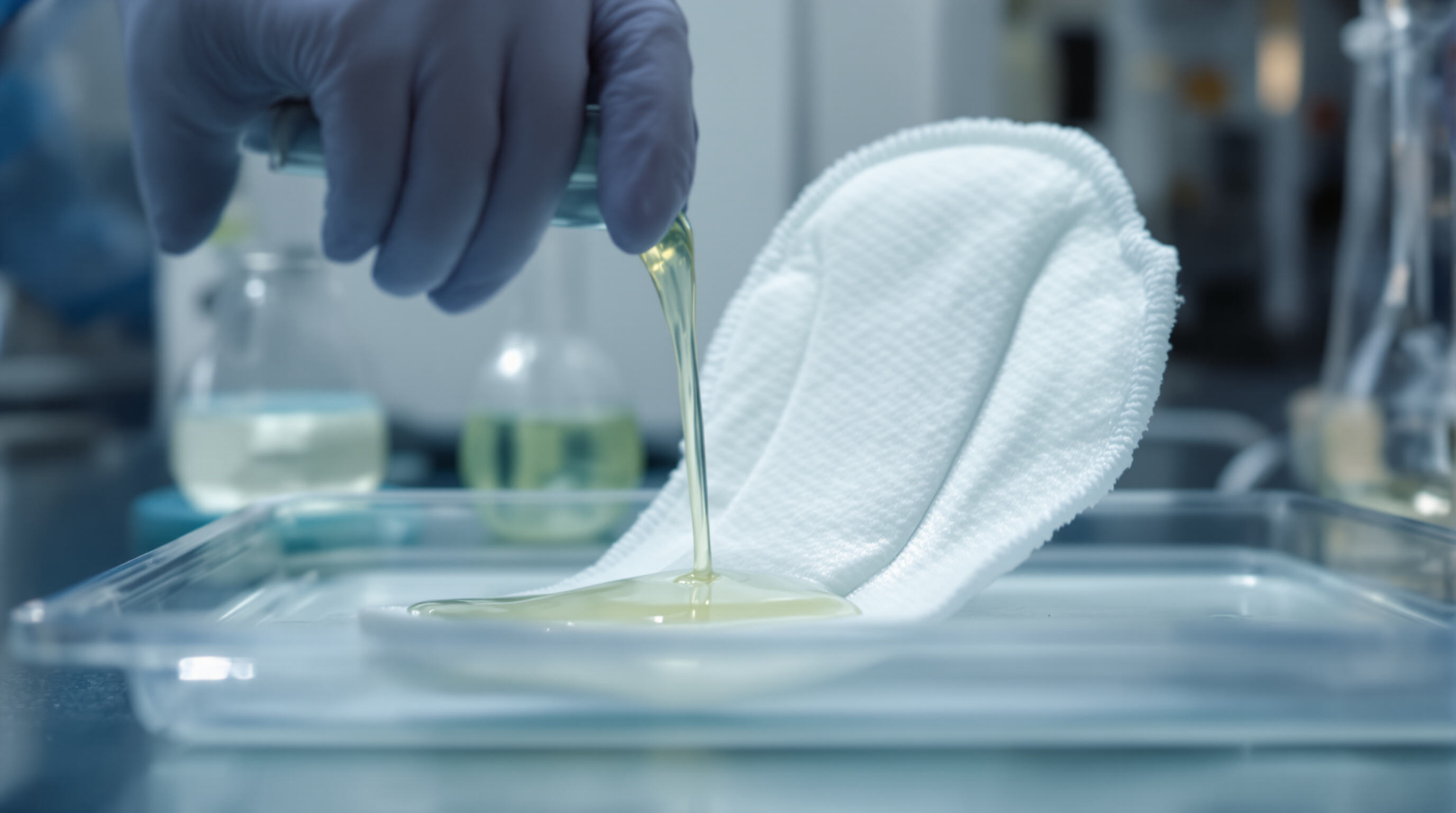

Použití superabsorbujícího polymeru (SAP) ve vložkách: chemie a funkce

Superabsorbující polymery, nebo také SAP, jsou obvykle vyrobeny z příčně zesíťovaného polyakrylátu sodného a mají úžasnou schopnost nasákat až 300krát více vlastní hmotnosti v kapalině. Pokud se použijí v nočních vložkách, vytvářejí tzv. hlavní vrstvu pro udržení. Fungují tak, že kapaliny přeměňují na gel pomocí procesu zvaného osmotický tlak, který v podstatě zabraňuje tomu, aby vložka znovu zmokla poté, co pohltí vlhkost. Výrobci těchto produktů tráví spoustu času úpravami, jako je velikost částic mezi přibližně 100 až 800 mikrometry, a upravují, jak těsně jsou polymerní řetězce spojené. Tato rovnováha pomáhá dosáhnout správné kombinace rychlosti, jakou materiál nasává kapalinu (alespoň 5 gramů za sekundu), a množství, které může udržet, než dojde k úniku, což podle většiny průmyslových norem musí být více než 60 gramů slané vody.

Optimální koncentrace SAP pro specifikace produktu nočních hygienických vložek

Podle odhadů z roku 2023 je pro 12hodinovou ochranu zapotřebí u nočních vložek 40–60 % SAP hmotnostně. Příliš vysoká koncentrace (65 %) narušuje pružnost a zvyšuje objem, zatímco nedostatečné množství (<35 %) hrozí únikem tekutin při vysokém zatížení (4,7 L/m²). Nezávislé testy potvrdily, že formulace s 55 % SAP udrží hodnotu přísáklivosti ≤0,15 g i pod tlakem 1,2 kg.

Srovnání typů SAP: sodná sůl polyakrylové kyseliny vs. nové generace hydrogelů

Tradiční sodná sůl polyakrylové kyseliny dosahuje absorpce 18–22 g/g, ale ztrácí 17 % účinnosti v prostředí s vysokou salinitou. Nové hydrogely na bázi celulózy nabízejí kapacitu 15–18 g/g a zároveň o 22 % vyšší pružnost, což umožňuje jádra tenčí o 0,3 mm. Studie z roku 2024 zjistila, že hydrogelová jádra snížila boční úniky o 29 % během testování pohybu.

Trend: Snížení závislosti na SAP pomocí hybridních absorbujících systémů

Aby čelili environmentálním obavám, 68 % výrobců OEM nyní kombinuje SAP s rostlinnými vlákny (bambus, bavlna) a částicemi aerogelu. Tyto hybridní materiály dosahují 85 % výkonu čistého SAP a zároveň využívají o 35 % méně polymerů. Jedna z formulací s 50/50 směsí dřevěné celulózy a SAP zajistila 9hodinovou ochranu proti úniku a snížila emise CO2 o 41 % (EcoHygiene Initiative 2023).

Dýchací povrchové vrstvy, integrita spodního materiálu a inovace v oblasti ekologických materiálů

Inovace zahrnují netkané materiály s hmotností 23 gsm s laserově vytvořenými otvory (≤1,2 sekundy pro průtok) v kombinaci s biopolymerovými spodními vrstvami z PLA-PHB. Tyto materiály snižují vlhkost pokožky o 33 % ve srovnání s PE fóliemi, přičemž udržují hydrostatický odpor ≥85 kPa. Vzhledem k tomu, že více než 47 % spotřebitelů dává přednost vložkám obsahujícím alespoň 30 % rostlinných materiálů, výzkum a vývoj se urychluje v oblasti alternativ k SAP z mořských řas.

Strategie personalizace pro cílové trhy a konkrétní případy použití

Přizpůsobení délky, šířky a konstrukce křídel vložek pro noční ochranu

Většina nočních vložek měří asi 34 až 38 centimetrů v délce a obvykle jsou vybaveny speciálními křídlovými prodlouženími, která vyčnívají asi 7 až 9 cm přes běžné modely, aby vše zůstalo na místě. Podle některých nedávných tržních průzkumů z loňského roku téměř sedm z deseti lidí hledá při nákupu těchto produktů silný úchyt křídel, což výrobci nyní uvádějí minimálně 0,35 Newtonu na čtvereční centimetr pro kvalitní ochranu proti úniku. Šířky se obecně pohybují mezi 80 a 95 milimetry, což dobře funguje pro různé typy postav, aniž by byly příliš patrné pod oblečením. Tyto vložky také disponují speciálními zadními vrstvami, které zabraňují posunování po celou dobu noci, takže si uživatelé nemusí dělat starosti s tím, že se věci budou přesouvat během spánku.

Možnosti personalizace pro vstřebávací jádro a materiály u OEM výrobců

Postupné OEM výrobci nabízejí modulární koncepty, které umožňují značkám personalizaci:

- Koncentrace SAP (40–65 %)

- Udržitelné povrchové vrstvy jako bambusový viskózní materiál (≤18 gsm)

- Hydrofobní lepidla s bariérou s 92–96 % odolností proti průsaku tekutin

Tato flexibilita podporuje regionální přizpůsobení – hybridní jádra s recyklovanou celulózou snižují použití SAP o 25–30 % a přitom splňují normy ISO 11948-1.

Strategie: Sladění vývoje produktů s regionálními potřebami spotřebitelů

Co je nejdůležitější při návrhu produktu, opravdu závisí na tom, kde lidé žijí. Například hladina vlhkosti, místní zvyklosti a způsob nakládání s odpady hrají svou roli. Lidé v tropech například dávají přednost produktům s dýchacími potahy s průměrnou propustností kolem 8 gramů MVTR za 10 minut nebo méně, zatímco v chladnějších oblastech je naopak klíčová rychlá absorpce do tří sekund. Nedávný pohled na spotřebitelské návyky z roku 2023 odhalil také další zajímavé rozdíly. Zhruba polovina (54 %) spotřebitelů jihovýchodní Asie stále preferuje kompaktní složené balení, zatímco více než dvě třetiny (72 %) Evropanů si zvykly kupovat věci větších ekologických krabicích. Společnosti, které skutečně testují své produkty lokálně, a ne jen rozesílají standardní návrhy, zjišťují, že se lépe připojují ke zákazníkům. Tato skutečnost je potvrzena i čísly – výrobci uvádějí zhruba 40% zlepšení úspěchu na trhu, když přizpůsobí produkty konkrétním regionům, místo aby používali univerzální přístup.

Hodnocení OEM a zajištění kvality pro silně vstřebávající noční vložky

Hodnocení služeb OEM/ODM: inženýrské služby, výzkum a vývoj a technické kapacity

Při výběru OEM je důležité prověřit jejich inženýrské vybavení a výši investic do výzkumu a vývoje. Nejlepší společnosti využívají své znalosti proudění tekutin k doladění základních konstrukcí, aby mohly zabránit únikům po dobu až 12 hodin bez přestávky. Co opravdu záleží? Zaměřte se na přesnost jejich integrace SAP, kdy se směrodatná odchylka nesmí přesáhnout 5 %. Také stojí za zmínku ty výrobce, kteří disponují speciálními kanálovacími systémy, které skutečně zvyšují rychlost vstřebání až o 30 %. Pro každého, kdo chce od samého začátku všechno udělat správně, musí technické audity ověřit, zda výrobce zvládá validaci malých sérií, ideálně do 500 kusů, což dává smysl, pokud chceme udržet vývoj produktu pružný a přizpůsobivý potřebám trhu.

Standardy a certifikace kvality produktů (ISO, FDA, CE, GMP)

Dodržování norem ISO 9001 a FDA 21 CFR Part 801 odlišuje přední dodavatele. Výrobci, kteří mají certifikace ISO 13485 (lékařské prostředky) a OEKO-TEX® ECO PASSPORT, hlásí o 42 % méně stížností na úniky (studie o hygienických produktech z roku 2023). Nezbytné ověření zahrnuje:

- Dodržování GMP při manipulaci s SAP

- Dýchací materiály se značkou CE

- Validace ECOCERT® pro komponenty z organické bavlny

Protokoly o zkoušení vzorků: vstřebávání, pH, měkkost a podráždění pokožky

Laboratorní zkoušky podle ISO 11948-1 ověřují klíčové parametry výkonu:

| Testovací parametr | Cíl pro noční vložky | Metoda měření |

|---|---|---|

| Gravimetrická vstřebávavost | ≥15 g tekutiny/g jádra | Modifikovaná injekční metoda |

| hladina pH | 4,2–5,5 | IS 15412:2021 |

| Odolnost proti promočení | ≤0,5g úniku | Test řízené komprese |

Podklady splňující tyto referenční hodnoty snižují stížnosti na úniky přes noc o 67 % (Globální hygienická zpráva 2024).

Stanovení referenčních hodnot QC a postupů nezávislého auditu

Zavést statistickou regulaci procesu (SPC) pro sledování koncentrace SAP (tolerance ±3 %) a konzistence hustoty jádra (rozptyl ≤0,02g/cm³). Nezávislí auditoři specializující se na netkané hygienické výrobky vyřeší odchylky v výrobě o 58 % rychleji než interní QA týmy (Intertek 2024). Klíčové body auditu zahrnují:

- Řízení teploty aktivace SAP (38°C ±1°)

- Integrita ultrazvukového sražení křidélek (pevnost v tahu ≥5N/mm)

- Počty mikrobiální po sterilizaci (<10 CFU/g)

Sekce Často kladené otázky

-

Jaké jsou hlavní faktory určující vstřebávací schopnost hygienických vložek?

Hlavními faktory jsou kapacita a účinnost udržení tekutiny, které jsou klíčové pro prevenci úniků. -

Jak ovlivňují kvalitu hygienických vložek normy jako ISO 11948-1?

Tyto normy zajišťují, aby vložky prošly důkladným testováním a splňovaly vysoké standardy pro udržení tekutin a prevenci úniků. -

Proč se v hygienických vložkách používá SAP?

SAP (Super vstřebávací polymery) se používají pro svou schopnost vstřebat a udržet velké množství tekutiny, čímž zajišťují dlouhodobé sucho. -

Jaké inovace podporují ekologický návrh hygienických vložek?

Hybridní vstřebávací systémy využívající rostlinná vlákna a částice aerogelu snižují závislost na čistém SAP.