Tartós ragasztóválasztás szárnyas higiéniai betétekhez meleg éghajlatú tároláshoz

Ragasztók hőfeszültség alatti lebomlásának mechanizmusai

A hőmérséklet molekularánc-lebontást vált ki a nyomásérzékeny ragasztókban, csökkentve a kötési erőt 20–30%-kal, ha a hőmérséklet tartósan meghaladja a 35 °C-ot (Jiujutech, 2024). A polimerlánc lebontása exponenciálisan gyorsul – minden 10 °C hőmérsékletnövekedés 30 °C felett a ragasztó tárolási élettartamát megfelezi a viszkoelasztikus tulajdonságok visszafordíthatatlan változása miatt.

A nedvesség szerepe a ragasztók meghibásodásának gyorsításában

A nedvességfelvétel forró éghajlati körülmények között kettős degradációs mechanizmust eredményez. 85% relatív páratartalomnál a vízmolekulák kiszorítják a ragasztó-alkalmazási felület közötti kötéseket, és hidrolizálják a polimerláncokat. A szén-epoxi kompozitokon végzett kutatások azt mutatják, hogy a nedves hőterhelés 4 hét alatt 25%-kal csökkenti a kötések szilárdságát – ez kritikus kérdés a szárnyas egészségügyi betét trópusi raktárakban tárolt termékek esetében.

Nyomásérzékeny ragasztók kémiai instabilitása magas hőmérsékleten

A gyakori akrilát formulák 40 °C-on autooxidáción mennek keresztül, szabad gyököket képezve, amelyek rontják a ragadósságot és a peeling erőt. A szilikon hibridjei kiváló hőállóságot mutatnak, a kezdeti tapadás 85%-át megtartják 90 napig 45 °C-on, míg a gumi alapú ragasztók csupán 52%-ot.

Természetes és szintetikus ragasztók: teljesítmény trópusi klímákon

| A ragasztó típus | 35°C/85% RH teljesítmény (6 hónap) | Újrahasznosítási eredmény |

|---|---|---|

| Természetes gumi | 38% tapadásretenció | 2,1/5 |

| Szintetikus akrilát | 67% tapadásretenció | 4,3/5 |

| Szilikonhibrid | 89% tapadásretenció | 4,7/5 |

Növényi eredetű ragasztók 2,3-szor gyorsabban lebomlanak, mint a szintetikusok nedvességciklus-tesztek során, ezáltal korlátozva alkalmazhatóságukat olyan szárnyas higiéniai betétek esetében, melyek éves szavatossági időszakot igényelnek trópusi körülmények között.

Az éghajlat okozta anyagkárosodás és a szárnyas higiéniai betétek strukturális integritása

Hogyan befolyásolják a magas hőmérséklet és páratartalom a betét szerkezetét

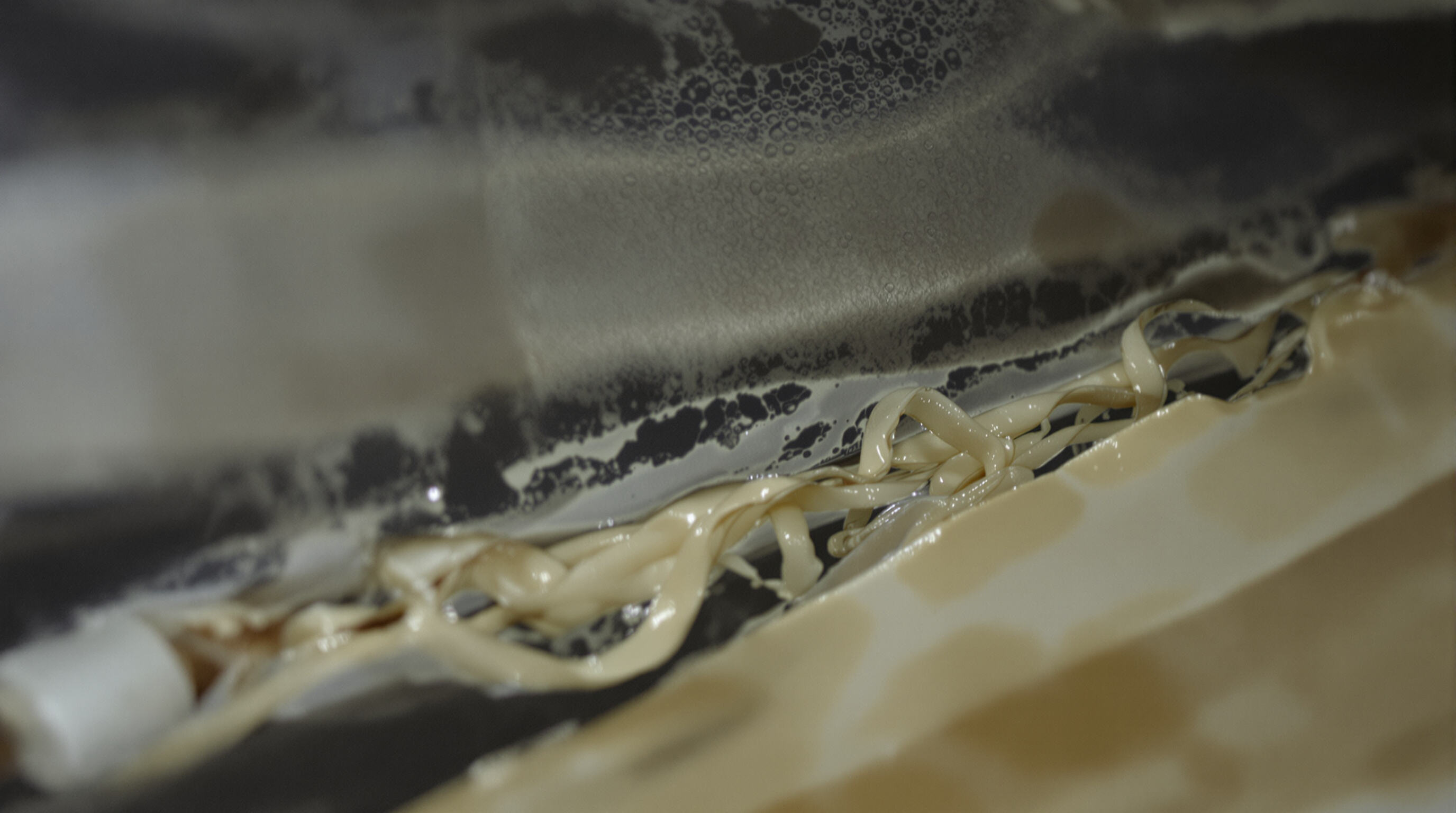

Amikor szárnyas higiéniai betétet 35 °C feletti hőmérsékleten és 85% feletti relatív páratartalommal rendelkező meleg, párás környezetben tárolják, a réteges szerkezete elkezd szétesni. A hőség minden anyagot megduzzaszt, így a nem szőtt anyagból készült felső réteg hajlamos leválni a belső szívórétegről. Ugyanakkor a magas páratartalom csökkenti a szárnyakat tartó ragasztó hatékonyságát. Ez a két probléma együtt azt eredményezi, amit mi leválási és csúszási helyzetnek nevezünk. Normál használat közben a különböző rétegek egyszerűen szétfiléződnek egymásról. Tesztek azt mutatják, hogy ez akár a termék gyorsított öregítése során akár a szivárgásvédelem hatékonyságának harmadával való csökkenését is okozhatja.

Nem szőtt alapanyagok anyagfáradása klímaterhelés következtében

A mai kereskedelmi zsebkendők többségében (kb. 78%-ban) polipropilén szálak találhatók, amelyek egyszerűen szétesnek, ha forró, párás körülmények között tárolják őket, mint amilyenek a trópusi éghajlati viszonyok. Indonesziai raktárakban végzett kutatások azt mutatták, hogy ezek a szálak akár 40% erejüket is elveszíthetik mindössze négy hónap alatt, ha nincs megfelelő klímaberendezés. A magas páratartalom kémiai lágyítóként működik, felgyorsítva az anyagba kevert papíralkotók lebomlását. A következő folyamat pedig már kevésbé vonzó. Az anyag felszínén azok a kellemetlen kis gombócok kezdenek el alakulni, amit pillingnek nevezünk, és sokkal lassabban szívja fel a folyadékokat, mint eredetileg tervezték. Mindenki, aki felemel egy ilyen sérült zsebkendőt, szinte azonnal észreveszi a hibát – általában kb. tíz másodperc alatt, miután hozzáér.

Esettanulmány: Zsebkendő-integritás terepi vizsgálata Délkelet-Ázsiai piacokon

Tizenkét hónapon keresztül végzett kutatás körülbelül 200 üzletben az egész Fülöp-szigeteken érdekes eredményeket hozott a szárnyas zsebkendőkkel kapcsolatban. Amikor a hőmérséklet 28 Celsius-foktól akár 42 fokig terjedt, a termékek közel kétharmada már jóval a vártnál korábban ragadási problémákat mutatott. Ezt különösen az ablakok közelében elhelyezett termékeknél figyeltük meg, amelyek a közvetlen napsütésnek voltak kitéve. Ezek a minták az ablak közelében tárolt zsebkendők szárnyragasztási tesztjeiket majdnem háromszor gyorsabban nem sikerítették, mint azok a zsebkendők, melyeket megfelelő tárolási körülmények között tartottak. Ez azt jelzi, hogy a csomagolástechnológiában biztosan van hely javulásra. A gyártóknak érdemes lenne olyan anyagok fejlesztését fontolóra venniük, amelyek képesek szabályozni a csomagoláson belüli hőmérsékletet, lehetőleg 30 Celsius-fok alatt tartva azt, hogy megelőzzék ezeket a problémákat már az elején.

Polcos élelmiszer-élethossz kihívások és csomagolási stratégiák trópusi tárolási környezetekhez

A szokásos szavatossági idő csökkenése szabályozatlan tárolási környezetekben

A szárnyas higiéniai betétek ragasztóanyaga gyorsabban degradálódik trópusi éghajlaton, ahol a tárolás gyakran meghaladja a 30 °C-ot 75–90% relatív páratartalom mellett. A szabályozatlan körülmények a klímaberendezéssel ellátott raktárakhoz képest 40–60%-kal csökkentik a szavatossági időt, rontva a szárnyak ragadósságát és szerkezeti integritását. A cellulózbázisú hátlaprétegek hidrolízise 30%-kal gyorsabb 35 °C / 85% RH-nál, mint mérsékelt övezetekben.

Adatpont: 40%-os ragasztóképesség csökkenés 6 hónapos tárolás után 35 °C / 85% RH-nál

A stabilitásvizsgálatok (ASTM F88 / ISO 2859-1) azt mutatják, hogy az akrilát alapú ragasztók 40%-os hántolószilárdságot veszítenek hat hónap elteltével a gyorsított trópusi körülmények között. Ez összhangban van a Délkelet-Ázsiából származó disztribútorok terepadatával, ahol nem légkondicionált létesítményekben tárolt termékek 22%-a nem felelt meg a ragadóssági teszteknek az elévülés előtt.

Csomagolás gáteresztőképessége és hatása a hosszú távú stabilitásra

A magas gátzáró tulajdonságú fémezett fóliák a nedvességgőz-áteresztést körülbelül 0,5 gramm/ négyzetméter/nap értékre csökkenthetik, ezáltal az adalékanyagok hatékonyságát három-hat hónappal meghosszabbítják. A nanocsillaggal bevont többrétegű laminátumok esetében ezek az anyagok jelentősen javított nedvességállóságot mutatnak a hagyományos alumínium kompozitokhoz képest. Egyes, a „Trends in Food Science & Technology” által közzétett tanulmányok körülbelül 58 százalékos javulást jeleznek ezen a területen. Ez különösen értélessé teszi őket olyan élelmiszer-csomagolási alkalmazásokban, ahol a termékeknek két évnél hosszabb ideig kell megőrizniük minőségüket, különösen meleg éghajlaton tárolva, ahol a hagyományos anyagok jóval hamarabb meghibásodnának.

Teljesítményelvárások: Szárnyragasztás megbízhatósága és a fogyasztói elvárások forró éghajlati körülmények között

Szárnyszerkezetek ragasztásának meghibásodási módjai tárolás és használat közben

A szárnyas higiéniai betétek három fő meghibásodási módját figyelhetjük meg trópusi klímákon: ragasztóanyag-likvidálódás 40 °C felett, nedvesség okozta kötéselgyengülés 80% relatív páratartalomnál, valamint mechanikus leválás a hordozóanyag elszakadásából. Terepvizsgálatok azt mutatják, hogy a nem klímaberendezéssel ellátott tárolás 2,5-szer több szárnyleválási panaszt okoz, mint a hőmérséklet-vezérelt raktározás.

Trend: Növekvő kereslet a visszahelyezhető, klímálló szárnyas ragasztók iránt

Délkelet-Ázsiában a fogyasztók 43%-a mára a „visszatapadási képességet” helyezi előtérbe termékértékelések során (2024 FemCare Fogyasztói Jelentés). Ez a kereslet ösztönzi a gumi-akrilát hibrid anyagok alkalmazását, amelyek hat nedvességi ciklus után (45 °C/90% RH) is megőrzik kezdeti tapadóerejük 85%-át.

Stratégia: Kétrétegű ragasztórendszerek tartósság növeléshez

A vezető gyártók aszimmetrikus ragasztórétegeket alkalmaznak:

- Alapréteg: Magas hőmérsékletálló akrilát (nyíró-ellenállás 75 kPa 50 °C-on)

- Fedőréteg: Szilikonmódosított ragasztó nedvességtűréshez

Ez a kialakítás csökkenti a páratartalom okozta meghibásodásokat 60%-kal az öregítési próbák során, miközben megőrzi a 0,3 mm alatti profilvastagságot.

Ipari paradoxon: a vékonyság iránti fogyasztói preferencia szemben az ragasztósság ellenállóképességével

A piaci adatok ellentmondást tárnak fel: a 2,3 mm-nél vékonyabb termékek a vásárlások 70%-át teszik ki, de 38%-kal gyengébb eredményt érnek el a szárnyas ragasztás vizsgálatokban. A fejlett nem szőtt alapanyagok lézerrel perforált ragasztó zónákkal egyre inkább megoldást kínálnak a vékonyság és a megbízható ragasztás egyensúlyának biztosítására.

Tárolható ragasztótechnológiák értékelése szárnyas higiéniai betétekhez

Akrilát alapú ragasztók: hőállóság és teljesítményadatok

Az akrilát ragasztók dominánsak a hőálló összetételek között a UV-állóság és a 60°C feletti ellenállóképességük miatt. Ezek a ragasztók a 40°C-on három hónap elteltével is megtartják az eredeti 85%-os hámozószilárdságot (ASTM F1889), de teljesítményük csökken 70% RH feletti páratartalomnál – ezzel korlátozva hatékonyságukat nedves trópusi környezetekben.

Gumibázisú ragasztók: korlátok a nedves tárolási körülmények között

A természetes kaucsuk formulák 40%-os tapadóerőt veszítenek 30 nap alatt 35°C/85% RH körülmények között. A szintetikus változatok javított nedvességtűrést nyújtanak, de még mindig 2,7-szer gyorsabban degradálódnak, mint az akrilok gyorsított öregítés során, ezért nem alkalmasak hosszú távú trópusi készletre.

Elsődleges szilikon hibridek: stabilitás extrém hőmérsékleteken

A szilikon-polimerek hőmérsékleti ciklusokon (-20°C-tól 65°C-ig) való tapadást biztosítanak, túlszárnyalva a hagyományos ragasztókat. Egy 2025-ös gecko-inspirálta ragasztóvizsgálat 94% tapadásőrzést mutatott 120 hőmérsékleti sokk után, bár a gyártási költségek 35%-kal magasabbak, mint az akril alternatíváké.

Vizsgálati protokollok: ASTM F1889 és ISO 15223-1 ragasztó tartóssághoz

A gyártók az ASTM F1889 (lefejtéses tapadás) és az ISO 15223-1 (orvosi címkézés) szabványokat kombinálják a hosszú távú ragasztók érvényesítéséhez. A modern protokollok négyfázisú páratartalom-ciklusokat és szimulált testkörülményeket (37°C/95% RH) is tartalmaznak, amelyek tükrözik a valós trópusi tárolási és használati körülményeket.

GYIK

Miért következik be az érzékeny higiéniai betétek ragasztóanyagának minőségromlása?

A ragasztóanyag minőségromlása a magas hőmérsékletnek és a páratartalomnak való kitettség miatt következik be, amely molekuláris lebomlást és a nyomásérzékeny ragasztók kötőerejének csökkenését okozza.

Hogyan befolyásolja a páratartalom a ragasztóanyag teljesítményét?

A páratartalom a vízmolekulák hatására kiszorítja a ragasztó kötéseket és hidrolizálja a polimerláncokat, ezzel gyengítve a ragasztóanyag és a felület közötti kölcsönhatást.

Mely ragasztóanyagok működnek a legjobban trópusi klímákon?

A szilikon alapú keverékek működnek a legjobban trópusi klímákon, megtartva a kezdeti ragadósság magas százalékos arányát még hosszú ideig tartó magas hőmérsékleti és páratartalom-expozíció után is.

Hogyan lehet javítani a szárnyas higiéniai betétek szavatossági idejét meleg éghajlatokon?

A szavatossági idő javítható korszerű csomagolási technikák alkalmazásával, mint például magas gáthárító képességű metallizált fóliák vagy nanoclay bevonatú laminátumok, amelyek csökkentik a nedvesség átbocsátási rátáját.